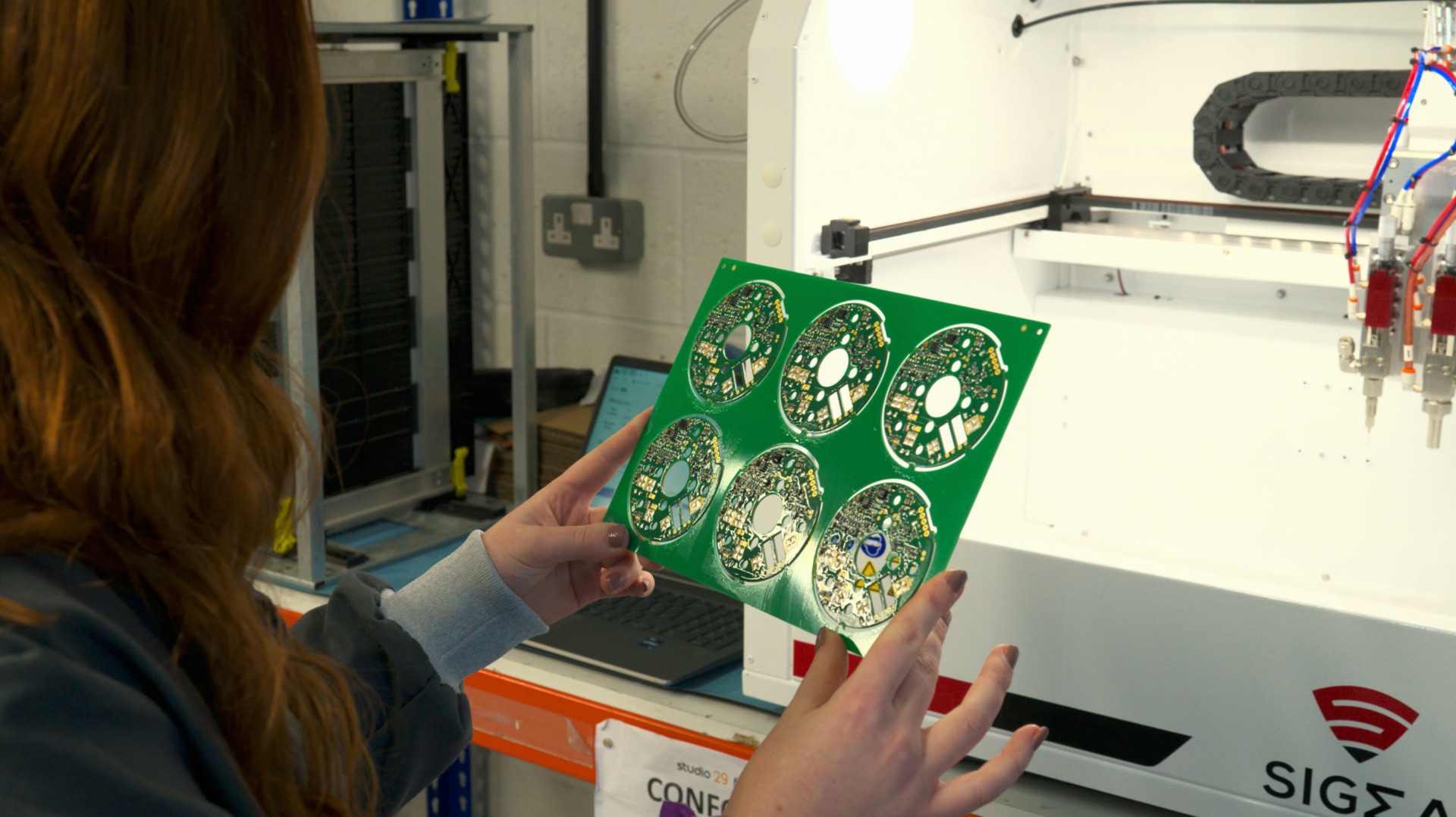

Our production facility is split into 3 key areas:

- SMT (Surface Mount Technology), THT (Through-Hole Technology) assembly and AOI (Automated Optical Inspection).

- PCBA Conformal coating.

- Full Box build and product assembly.

Our two SMT lines offer unique differences and flexibility, suitable for prototypes, small batches, and large scale production.

Including a fully automatic Stenciling and ‘Swiss made’ Pick-and-Place (PNP) machine can place over 12,000 components per hour, with extreme precision. Able to place 80mm wide components right down to 0201 components including fine pitch IC’s and BGA’s. This is perfect for NPI and small batch runs.

Our secondary 6-head PNP machine others repeatability and speed for medium to high production runs. Then to ensure the highest quality we complete fully AOI on every board as standard. Cable of manufacturing thousands of PCBA’s a week.

THT is still essential for most PCBA builds. Our expertise in both manual and machine based soldering offers speed and high quality for many high reliability markets.

Our production capabilities extend beyond PCBA build. We provide conformal coating services by hand and automated spray machine, ensuring your electronics are protected from environmental factors such as humidity and moisture.

To complement our electronics assembly we offer full in-house product assembly, including programming, testing and packing. All run through our ISO 9001 quality control processes.